Project

winch SHW8200-16-2/2-1 L3

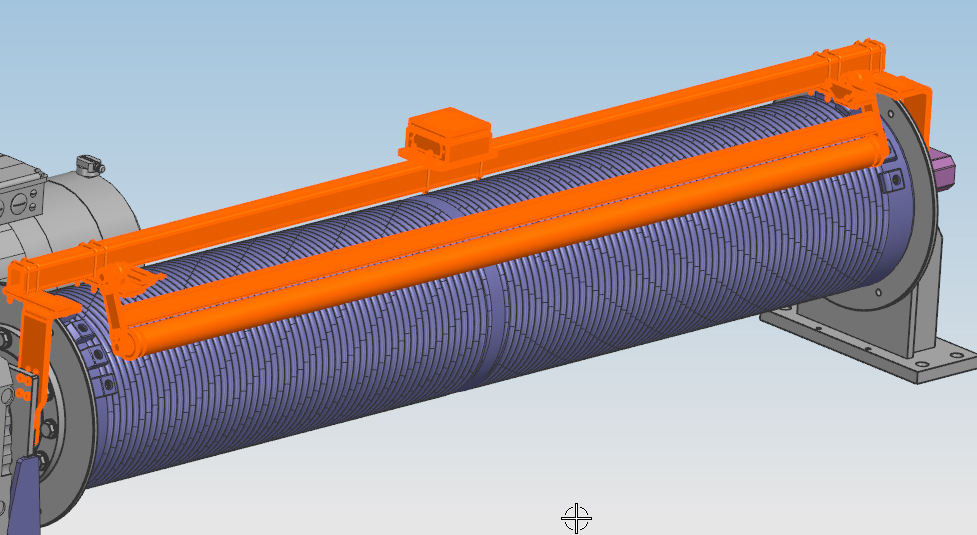

A stationary hoist is required for a cooling tower with a 142 m lifting height and 20,000 kg capacity. The SHW8 winch design is indispensable to comply with space restrictions and the requested high lifting speeds, including TVL hoisting. Incorporation of advanced safety features such as a secondary drum brake, cable overwinding protection, and geared limit switches.

Variable frequency drives (VFDs) are included for accurate load positioning at the installation point.

For projects like these, we supply custom-designed equipment to guarantee operational functionality and safety

20,000 kg capacity with 142 m lifting height at 19 m/min

Design

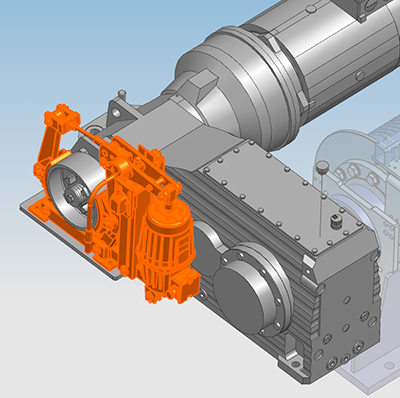

STAHL SHW8200 hoist with VFD for a 76 kW motor. Infinitely variable lifting speed from 0.38 to 19 m/min with remote control. SMC4 load weighing system with display mounted on the structure ceiling.

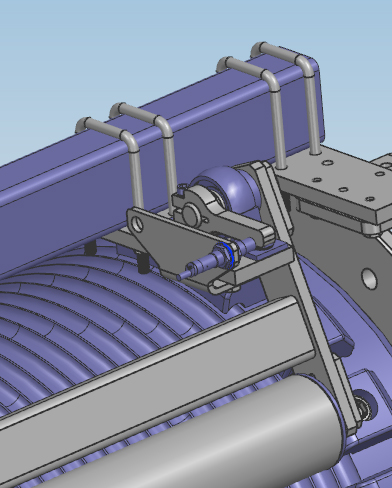

Cable overwinding prevention system using a floating traverse bar over the drum.

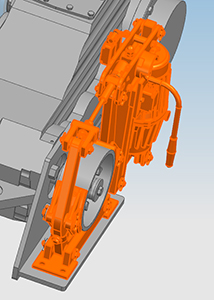

Motor with manual brake disengagement.

Secondary drum brake and geared limit switches.

Need help with something similar?

Get in Touch

Cable overwinding protection system

How the overwinding protection system works:

- Avoid Equipment Damage: Preventing the cable from winding or unwinding past its safe limit protects the cable, drum, and hoist components from damage.

- Safety: Protects operators and the surrounding area from potential accidents, including load drops caused by mechanical failure from cable overwinding.

- Preventative Measures: If the system detects imminent overwinding, the hoist automatically stops to prevent incidents.

This protection is essential in lifting systems to ensure equipment integrity and operational safety.

Electrohydraulic Braking System

Ventajas del freno electrohidráulico de tambor:

- Fiabilidad en condiciones exigentes: Estos frenos están diseñados para aplicaciones pesadas y condiciones industriales severas, donde se requiere un frenado confiable y duradero.

- Mantenimiento reducido: Los frenos electrohidráulicos de tambor tienn un diseño robusto que requiere menos mantenimiento que otros tipos de frenos mecánicos o eléctricos.

- Operación segura: El diseño basado en resortes para el frenado asegura que el sistema detenga la maquinaria en caso de fallo eléctrico, lo que es crucial en aplicaciones críticas de seguridad.