Modernizing with Wheel Blocks

Precision and perfection allow the restoration of overhead crane structures, no matter how old they may be

Crane kits, wheel blocks, or end carriages

The sustainability of recycled equipment

The modernization of an overhead crane can be considered a sustainable option due to improvements in energy efficiency, emission reduction, enhanced durability, improved safety, and the adaptability it can provide. These enhancements contribute to sustainability by reducing the consumption of natural resources, greenhouse gas emissions, and waste, while simultaneously protecting the health and safety of workers.

Once it is ensured that the bridge structure and end trucks are in good condition, the modernization of the electrical system, hoist, and wheel blocks will turn what is essentially an obsolete crane into a modern system with all the safety features required for a secure and reliable operation.

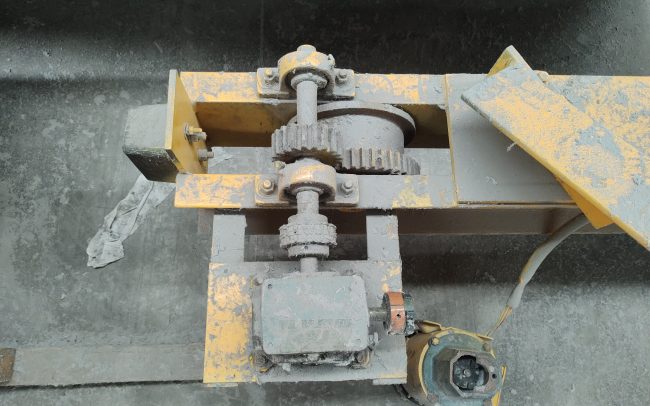

BEFORE

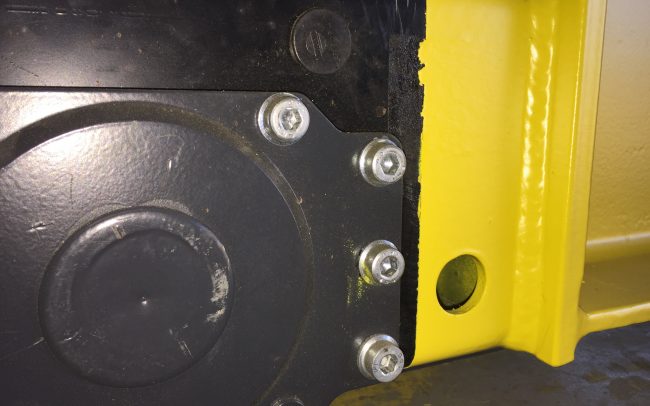

AFTER

1. ENERGY EFFICIENCY:

Modernized overhead cranes often incorporate more energy-efficient technologies. This may include more efficient motors, variable speed control systems, and regenerative braking, among others. These improvements can significantly reduce energy consumption and therefore, lower the carbon footprint of the equipment.

2. EMISSION REDUCTION:

By enhancing energy efficiency, the greenhouse gas emissions associated with the operation of the overhead crane are reduced. This contributes to the mitigation of climate change and supports the achievement of emission reduction targets.

3. GREATER DURABILITY:

The modernization of an overhead crane can include the replacement of worn or outdated components, which extends the equipment's service life. This reduces the need for manufacturing new overhead cranes, thereby decreasing the consumption of natural resources and the generation of waste.

4. ENHANCEMENT OF SAFETY:

The modernization of an overhead crane can include the installation of additional safety systems, such as proximity sensors, load detection systems, and remote control systems. These improvements can reduce the risk of accidents and injuries, which in turn contributes to sustainability by protecting the health and safety of workers.

Innovative: Design with Wheel Blocks

Our wheel blocks feature three coupling methods,

- Welding

- Bolting

- Screwing

The adaptability to your needs allows for universal integration, responding to highly reliable modernization.

-

Reliable: Smooth Movements

The silent gears of our gearmotors ensure that startup and acceleration are smooth. Braking, determined by precise calibration of the disc pressure, allows for precision work, avoiding abrupt movements. Thus, our components contribute to high operational safety and reliability.

- The standard model includes two speeds with a 1:4 ratio or a continuous speed with frequency regulation offering a 1:10 ratio.

- Reduced maintenance permanent lubrication gear system

- Smooth travel characteristic thanks to its integrated inertia mass and a quiet gear system.

- Secure Power Transmission via Splined Shafts According to DIN 5480

- Complete Equipment: Integrated disc brakes, Integrated torque limiter

Zentratec

Crossing the boundary of what's possible

Have a project in mind?

GET ADVISED