Project SHW8200-16-2/2-1 L3

Project

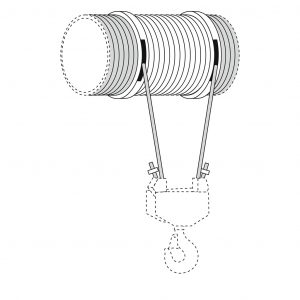

winch SHW8200-16-2/2-1 L3

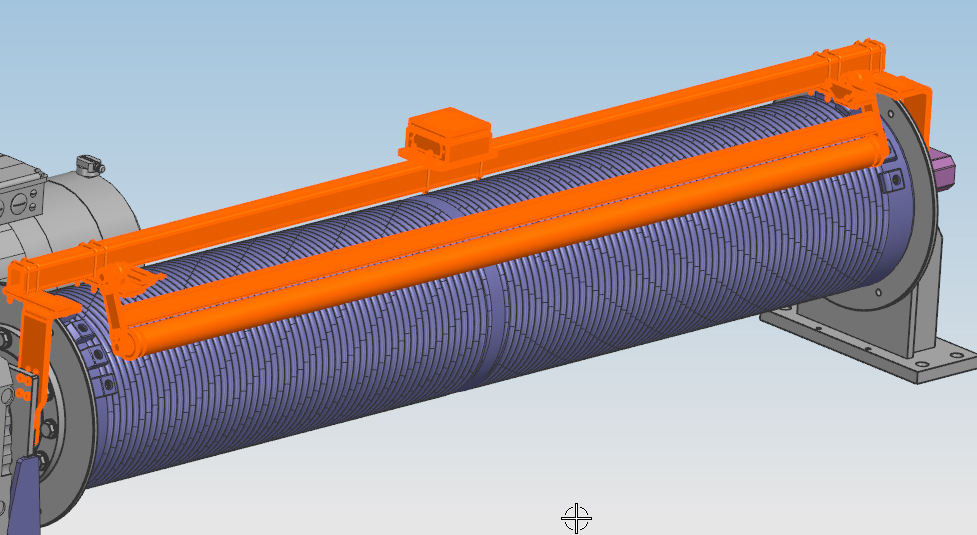

A stationary hoist is required for a cooling tower with a 142 m lifting height and 20,000 kg capacity. The SHW8 winch design is indispensable to comply with space restrictions and the requested high lifting speeds, including TVL hoisting. Incorporation of advanced safety features such as a secondary drum brake, cable overwinding protection, and geared limit switches.

Variable frequency drives (VFDs) are included for accurate load positioning at the installation point.

For projects like these, we supply custom-designed equipment to guarantee operational functionality and safety

20,000 kg capacity with 142 m lifting height at 19 m/min

Design

STAHL SHW8200 hoist with VFD for a 76 kW motor. Infinitely variable lifting speed from 0.38 to 19 m/min with remote control. SMC4 load weighing system with display mounted on the structure ceiling.

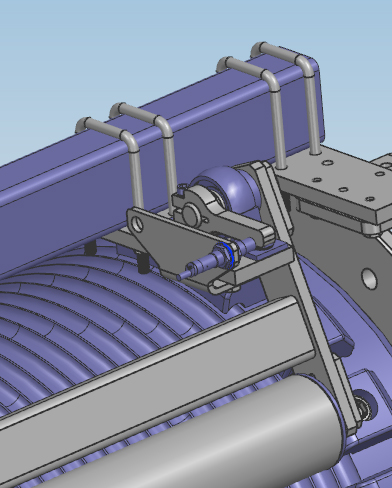

Cable overwinding prevention system using a floating traverse bar over the drum.

Motor with manual brake disengagement.

Secondary drum brake and geared limit switches.

Need help with something similar?

Get in Touch

Cable overwinding protection system

How the overwinding protection system works:

- Avoid Equipment Damage: Preventing the cable from winding or unwinding past its safe limit protects the cable, drum, and hoist components from damage.

- Safety: Protects operators and the surrounding area from potential accidents, including load drops caused by mechanical failure from cable overwinding.

- Preventative Measures: If the system detects imminent overwinding, the hoist automatically stops to prevent incidents.

This protection is essential in lifting systems to ensure equipment integrity and operational safety.

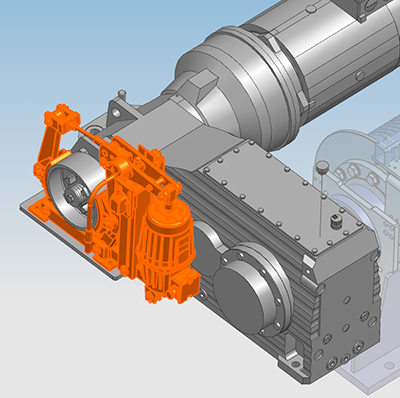

Electrohydraulic Braking System

Ventajas del freno electrohidráulico de tambor:

- Fiabilidad en condiciones exigentes: Estos frenos están diseñados para aplicaciones pesadas y condiciones industriales severas, donde se requiere un frenado confiable y duradero.

- Mantenimiento reducido: Los frenos electrohidráulicos de tambor tienn un diseño robusto que requiere menos mantenimiento que otros tipos de frenos mecánicos o eléctricos.

- Operación segura: El diseño basado en resortes para el frenado asegura que el sistema detenga la maquinaria en caso de fallo eléctrico, lo que es crucial en aplicaciones críticas de seguridad.

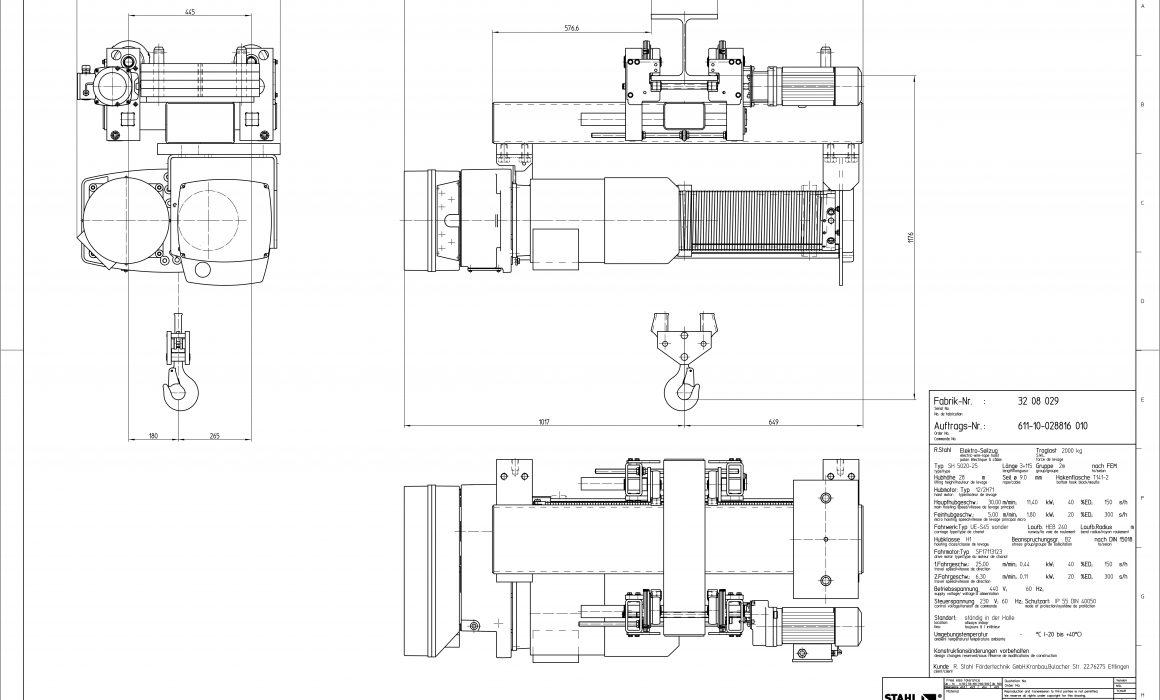

Project AS7125-12 4/1 L2 DUE-M77R

Project AS7125-12 4/1 L2 DUE-M77R

Project

AS7125-12 4/1 L2 DUE-M77

Our AS7125-12 4/1 L2 DUE-M77 hoist makes handling heavy machinery up to 45 tons a routine operation.

- 15.65 m lifting height

- Articulated trolley featuring 4 reliable travel drive units

- Smooth and nimble traversing on curves with a 2750 mm radius.

- Slow hoisting speed of 0.5/3 m/min for accurate equipment positioning.

Design

The hoist features an articulated single-girder trolley with 4 x 4 wheels and guide rollers designed for 2,750 mm radius curves, housed in a structural steel cage that delivers maximum rigidity. Its robust construction enables millimeter-level positioning without vibration in the hoisting mechanism. The powerful motor lifts 45 tons via a 4-part cable reeving arrangement, eliminating unwanted oscillation. The 15.65 m lifting height provides ample clearance for handling bulky machinery components

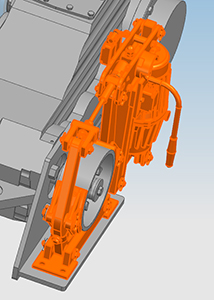

Ratchet Brake

The project required a secondary brake to ensure that the rollers of the mills could be suspended indefinitely for access to the interior of the machinery. We included a ratchet brake mounted on the drum, which is ideal for the application.

The pawl mechanically engages, keeping the drum locked. It will only release the brake through an electromagnetic actuator.

Project AS7100-12ZW 2/2-1 L4

Project

AS7100-12 ZW 2/2-1 L4

A stationary hoist is required for a cooling tower with a 96 m lifting height and 20,000 kg capacity. The AS70 hoist design is ideal for this project, featuring a robust frame that enables coupling two hoists using anti-rotation steel cable with an integrated hook block and equalizing pulley. The availability of different motors and lifting speeds allows perfect adaptation to project specifications.

We exceed customer expectations in reliability and operational speed, critical since maintenance shutdowns for turbines and motors must be kept to an absolute minimum.

For projects like these, we supply equipment with lifting heights reaching 200 m in multiple load capacities.

20,000 kg and 96 m lift height at 17 m/min

Design

Two synchronized AS 7100-12 hoists achieve a 96 m lifting height. Their dual '12/2H73' motors, totaling 2 x 29 kW, deliver speeds of 2/17 m/min. Substantial power reserves enable lifting the full load in a single operation. The design incorporates a dual ratchet brake system that detects overspeed conditions and engages to stop the load smoothly and safely. These brakes also secure the drums when the equipment is idle. Additionally, the hoists feature manual brake release capability for safe load lowering during power outages.

Need help with something similar?

Get in Touch

Ratchet Brake

The project required a secondary brake to ensure that the rollers of the mills could be suspended indefinitely for access to the interior of the machinery. We included a ratchet brake mounted on the drum, which is ideal for the application.

The pawl mechanically engages, keeping the drum locked. It will only release the brake through an electromagnetic actuator.

Calibrated Steel Chain

Steel Chain for Electric Hoist

Find the right chain for your STAHL hoist

We provide original replacement parts, without compromise:

Service Manuals

Download information for your 'R', 'T', or 'ST' hoist

built on the STAHL CraneSystems platform.

4 x 12 mm galvanized carbon steel chain ('T 05', ST 05 / STD 05)

5 x 16 mm galvanized carbon steel chain ('ST 10 / STD 10')

6 x 18.6 mm galvanized carbon steel chain ('R6', 'T3')

7 x 21.9 mm galvanized carbon steel chain ('R12', 'T4', 'ST 20 / STD 30')

9 x 27 mm galvanized carbon steel chain ('R20', 'T5', 'ST 30 / ST 32 / STD 50 / STD 60')

11.3 x 31 mm galvanized carbon steel chain ('ST50')

11.3 x 31 mm galvanized and heat-treated carbon steel chain ('ST60')

Why It's Important to Use the Correct Load Chain

The load chain is a key safety part of your electric hoist. For STAHL chain hoists, you must use the original hoist load chain. This isn't just a suggestion; it's about keeping the hoist and its load chain working safely for every lifting task.

Each load chain is a specific item made to perfectly fit the hoist's internal parts. This is the best way to guarantee a safe operation. This fit lets the load chain run smoothly and prevents the chain from wearing out too fast or breaking down completely. When you use a non-genuine replacement chain, you introduce risk. This kind of chain can create serious problems. The authentic load chain is the only item sold by us for this purpose. We want to ensure every chain you use is the right one.

Zentratec offers load hooks and all original replacement parts for the correct functioning of your hoist

How to Order Your Replacement Chain

When you are ready to shop for a new load chain for your hoist, check first to know its model.

You can usually find this information for your specific chain on a small data plate on the hoist's body. Once you find the model, you can match it to the list on this page to identify the correct load chain.

If you are not sure about the model or the correct quantity of chain you need to order, please contact us directly.

Need spares?

Reach out!To find your serial number:

DOWNLOAD MANUAL

We guarantee the supply of original spare parts for your STAHL CraneSystems hoists.

STAHL CraneSystems

Frequently Asked Questions

How do I know when it's time to replace my hoist load chain?

You should inspect your chain regularly for signs of wear, such as stretching (an increase in length), nicks, gouges, corrosion, or twisted links. Refer to your hoist's service manual for specific measurement tolerances. If you find any damage, the chain must be replaced immediately.

Can I use a chain from another manufacturer, like Harrington or Yale, on my STAHL hoist?

No. You must only use an original STAHL load chain for your electric hoist. Chains from other brands are not designed for the specific tolerances of STAHL's internal components, and their use will void the warranty and create a serious safety risk.

What is the benefit of a "galvanized" carbon steel chain?

Galvanizing is a process that coats the steel chain in a layer of zinc. This provides excellent protection against rust and corrosion, which is especially important in humid or harsh industrial environments.

Do you sell any chain accessories, like chain bags or hooks?

Yes, we offer a full collection of original parts, which includes load hooks, chain bags, and all other items needed for the correct and safe use of your hoist.

Is there a way for a human to review my order to make sure I selected the right item?

Absolutely. The best way is to contact us directly. Our team will personally review your needs and prove you are ordering the correct hoist load chain for your specific model.

Do your chain hoists require lubrication?

Yes, proper lubrication is necessary for the longevity and safe operation of the load chain. Please consult your service manual for the recommended type of lubricant and the correct maintenance schedule.

Can I repair a single damaged link on my hoist load chain?

No, you should never attempt to repair a damaged link on a load chain. A chain is only as strong as its weakest link, and any repair would create a dangerous weak spot. For safe lifting, the entire chain must be replaced. Every load chain is sold as a single, continuous item; for this reason, it is not safe to use a repaired chain on your hoist.

Is the load chain for an electric hoist the same as a general-purpose chain?

No, they are very different. A hoist load chain is a highly engineered item from our collection, specifically designed for overhead lifting. It's made from special, high-strength steel and is calibrated to fit the pockets of the hoist's lift wheel perfectly. You must never use a standard hardware chain on your hoist, as it is not designed to handle the load and will fail.

Require a new chain?

Get in TouchCoating

Hoist Coating

Protection Against Aggressive Media

In aggressive environments that compromise the reliability and lifespan of our equipment, it is important to pre-select the type of protective coating to be applied. Strict adherence to international standards ensures the quality of our finishes. Although all screws or exposed metal parts are galvanized, it is advisable, where possible and without affecting the operability of the equipment, to coat them with paint.

DIN EN ISO 12944 Part 6

Tomamos muy en serio la protección de su equipo. Por ello ofrecemos una grán variedad de recubrimientos desarrollados por expertos para satisfacer sus necesidades. Todo recubrimiento se realiza en fábrica STAHL. Solo así garatizaremos la compatibilidad de los componentes y calidad que se su proyecto exige.

Our equipment has been designed to withstand over 20 years of operation. Therefore, the importance of a coating is key to its preservation. STAHL provides modern painting applications, which we will present to you below.

A20/80: The standard for our hoists is an 80-micron coating in green and anthracite for motors. This protection is sufficient for most situations in the industrial market.

For applications according to your requirements regarding paint layer thicknesses and color, we suggest contacting us. Together we will find your best option.

Electrostatic Paints

Our standard coatings include various paints that can be identified according to the attached "coatings chart". In the subsequent links, we provide the technical data sheets for these paints.

FINISHES AND THICKNESSES FOR A20 COATING

Our solvent-based coatings are complex applications of polyester and epoxy-based paints that can be identified according to the attached "coatings chart". In the subsequent links, we provide the technical data sheets for these finishes and thicknesses.

SOLVENT-BASED EPOXY PAINTS COMBINED WITH ELECTROSTATIC PAINTS

Our solvent-based coatings are complex applications of polyester and epoxy-based paints that can be identified according to the attached "coatings chart". In the subsequent links, we provide the technical data sheets for these paints.

FINISHES AND THICKNESSES FOR COATINGS A20, A20A, A30

Our solvent-based coatings are complex applications of polyester and epoxy-based paints that can be identified according to the attached "coatings chart". In the subsequent links, we provide the technical data sheets for these finishes and thicknesses.

Repairs

Our coatings occasionally require repairs. For instance, when the equipment is struck and a crack is formed. In the following links, we outline the technical data sheets for carrying out professional repairs professionally.

How To Choose the Right Finish for Your Environment

The kind of work environment your hoists operate in determines the best coating to use. A hoist in a humid, salty coastal environment will require a much different finish than one in a dry, indoor facility.

We offer a range of proven coating applications to protect your product from corrosion, chemicals, and wear. If you get the finish right from the start, you'll prevent problems like rust and paint peeling later on.

Custom Designed Protection for Hoist Systems

All our protective coatings are factory-applied to ensure the highest quality. This process creates a stronger bond and a more uniform finish than painting on-site.

With us, you can get custom-designed solutions for even the most demanding applications. Whether you need a specific thickness, a special color, or a multi-layer system for your hoist systems, we can develop a custom coating that meets your needs.

Frequently Asked Questions

What do the C-ratings (C2, C3, C4, C5) mean?

The C-ratings come from the DIN EN ISO 12944 standard and classify how corrosive an environment is. C2 is a low-corrosion environment (like a heated workshop), while C5 is a very high-corrosion environment (like offshore or coastal industrial areas). We match the hoist coating to the C-rating of your workplace.

What is the best way to prevent the hoist coating from peeling?

The factory application process is the best defense against peeling. It creates a very strong bond to the metal. To maintain the finish, avoid deep scratches or impacts that break the paint surface and expose the metal underneath.

How do I repair the coating if it gets chipped or scratched?

Our packet features detailed manuals for repairs. Follow the instructions to properly patch the damaged area and restore the protective layer on the product.

Why is a factory-applied finish better than painting a hoist on-site?

A factory-applied finish is prepared, applied, and cured in a controlled environment. This process is a proven way to achieve the correct thickness and a superior bond, which is very difficult to replicate in the field.

Are these special coatings available for all STAHL hoist systems?

Yes, we can provide custom-designed protective coatings for our full range of hoist systems. We will work with you to determine the best product and finish for your specific model and its intended applications.

What is the difference between an epoxy and a polyester coating?

Epoxy coatings are known for their excellent hardness and chemical resistance, making them great primers. Polyester coatings provide a durable top finish with excellent color and gloss retention, especially against sunlight. Many of our advanced hoist coating systems use both in different layers.

What is the standard finish on your hoists if I don't ask for something custom?

Our standard coating is the A20/80 finish. This is a proven, high-quality coating that is suitable for the majority of general industrial applications.

How do I decide which coating application I need?

The best way is to talk with us. Tell us about your work environment, what materials the hoists will be exposed to, and we will help you select the right hoist coating. We will both agree on the best solution.

What form do I need to fill out to get a quote for a custom finish?

You don't need to fill out a specific form to start. The best first step is to contact our team directly through the information on this page. We can discuss all your options and get the process started.

Get in Touch

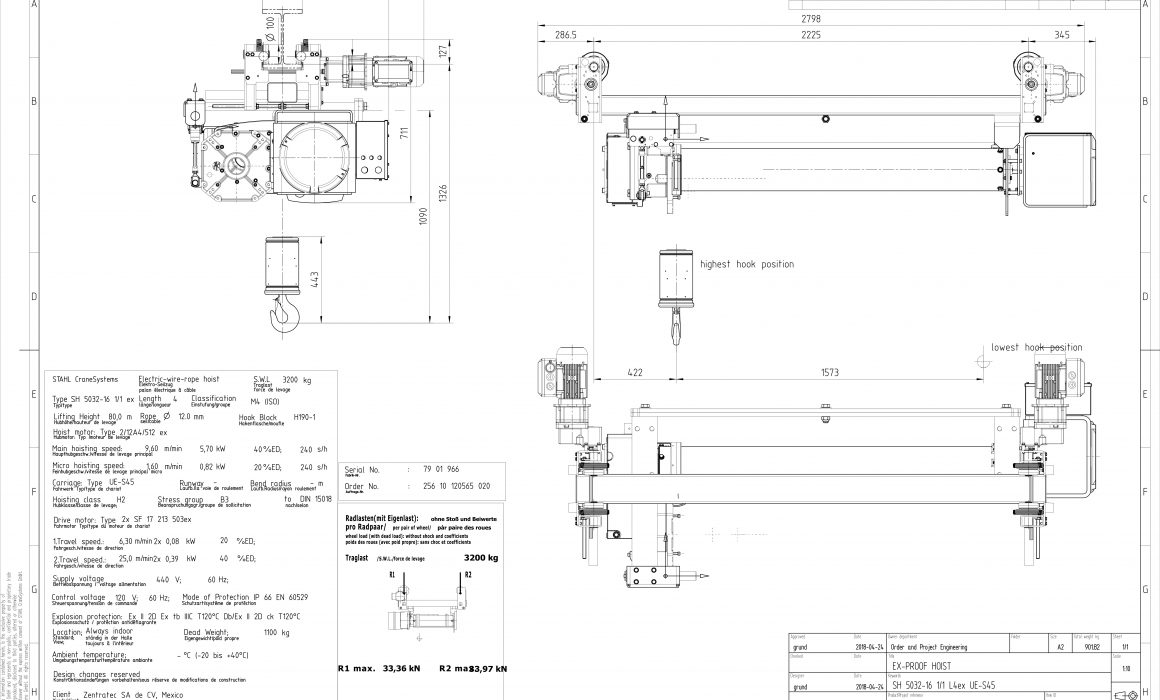

contact formProyecto SH5032-16 1/1 ex L4 – Planta de Coque

Project SH5032-16 1/1 ex L4

Material Handling

Project SH5032-16 1/1 ex L4

This project required ATEX explosion-proof hoists capable of 80 m lifting heights. Severe environmental conditions necessitated Ex IID Ex tb IIIC T120°C classification with IP66 protection rating. The perfect application for STAHL hoists.

We delivered a total of 4 hoists with different capacities and lift heights.

Design

• ATEX explosion-proof wire rope hoist with monorail trolley for straight beam

• 3,200 kg capacity, single-part reeving

• Explosion protection: Zone 1 / Ex II 2D Ex tb IIIC T120°C

• IP 66 rating

• 80 m lifting height

• Hook with thermal-sprayed bronze coating

• Bronze wheels

Zone 1-rated control panel

The control panel is integrated into a flameproof cast iron housing. Engineering had specific requirements such as cables marked with custom nomenclature, stainless steel engraved nameplates, and fuses built into the main circuit breaker.

Project SH6020-32 8/2-1 L5

Project SH6020 ZW-32 8/2-1 L5

Design

• Two hoists mounted on a suspended monorail frame

• Gearmotors exclusively designed for high-cycle lifting applications

• IP55 protection, IP66 optional.Thermal class F. Temperature control via PTC thermal probes

• SMC22 electronic system for overload management and motor performance monitoring

• Dual drum for 42.8 m vertical lift (TVL)

• Hoist and travel limit switches

• Rigging configured for saltwater immersion

• Custom-designed frame to accommodate dual hoist geometry

• Stainless steel identification plates

• Siren and strobe beacon

• Remote control and pendant pushbutton station for emergencies

• State-of-the-art LED floodlights to illuminate loading area

• Comprehensive documentation and certifications verifying regulatory compliance

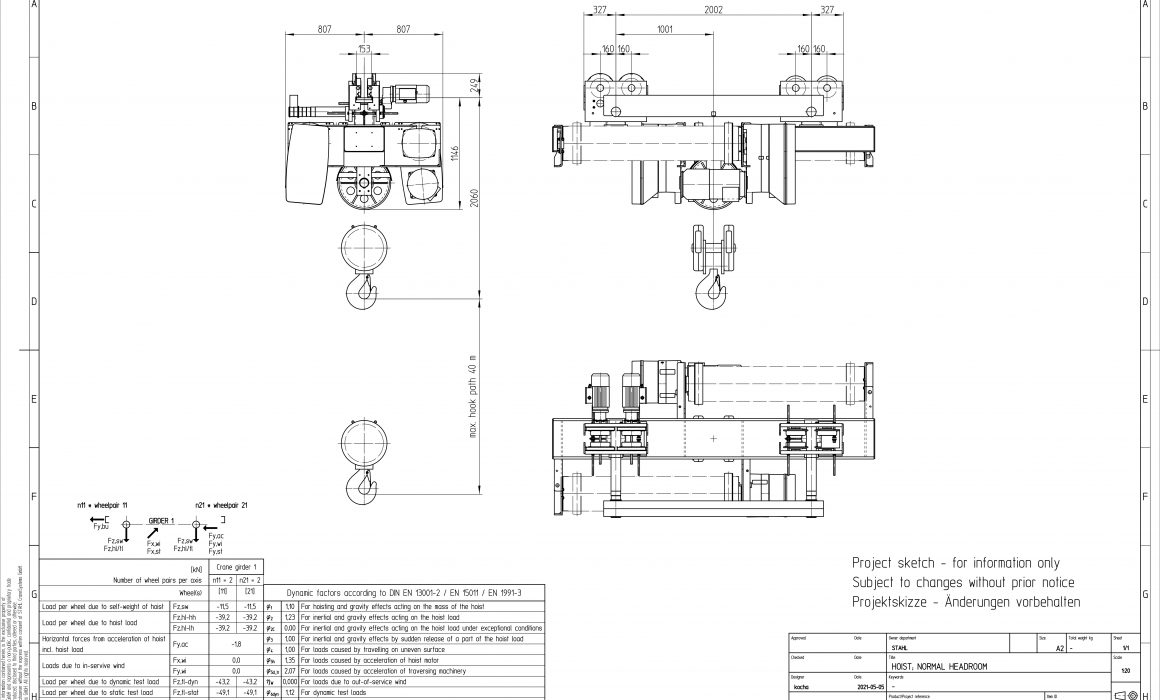

Project SH 5020-25 2/2-1 UE especial

Project SH5020-25 2/2-1 L3 UE

Material Handling

Modernizing

SH5020-25 2/2-1 L3 UE

2005: Our client's building design required a hoist on a single-girder trolley mounted perpendicular to the bridge crane to meet required approach dimensions. The design geometry necessitated true vertical lift capability, so we selected a 2/2-1 reeving arrangement to achieve the desired result.

This unit operates three shifts daily with high duty cycles and a

28 m lifting height.

2021: After reaching end-of-life following over 15 years of service, our client contacted us for equipment replacement.

The new hoist is an exact replacement that complies with current updated safety standards, now enhanced with radio remote control for improved operational safety.

Design

• Cable hoist with design perpendicular to the bridge, mounted on single-girder trolley for straight beam.

• 2,000 kg capacity with 2/2-1 reeving

• 28 m lift height

• Lifting speed 17m/min

• IP 66 rating

• HBC radio remote control with custom functions

• Hoist assembly perpendicular to carriage

The unit after 15+ years of service.

Custom Solutions:

The modular design of our hoists allows for countless adaptations to integrate into your facilities. We'll advise you to meet your challenges.

Reach out with any questions: