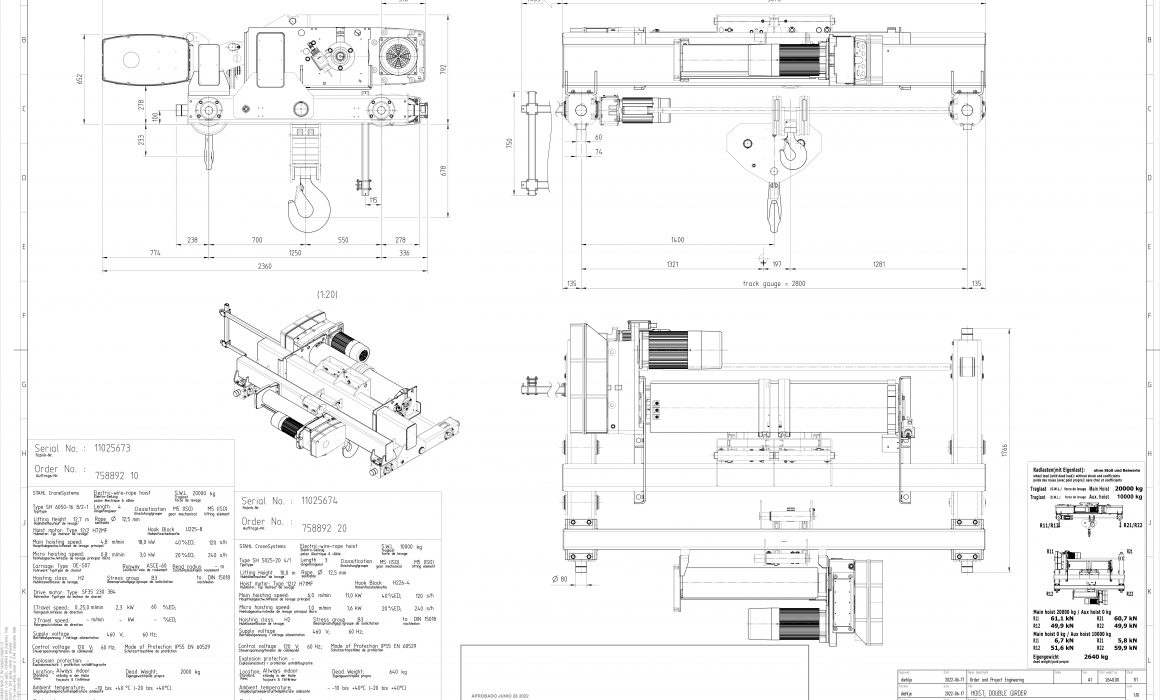

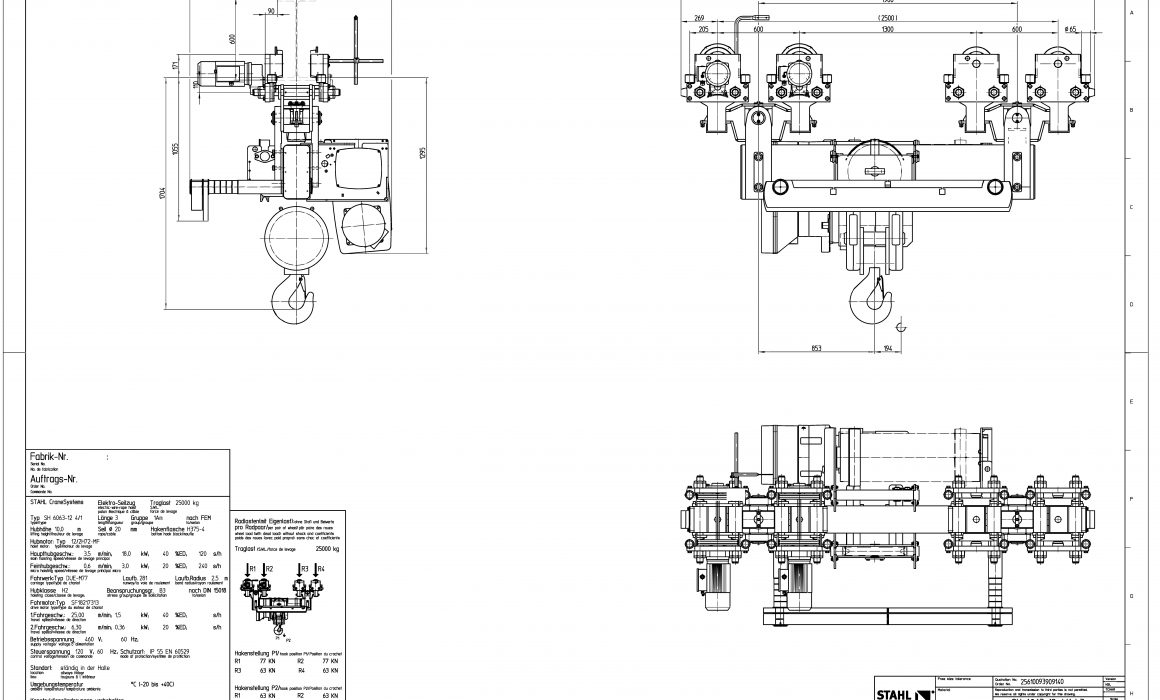

Project SH6050-16 8/2-1 L4

Project

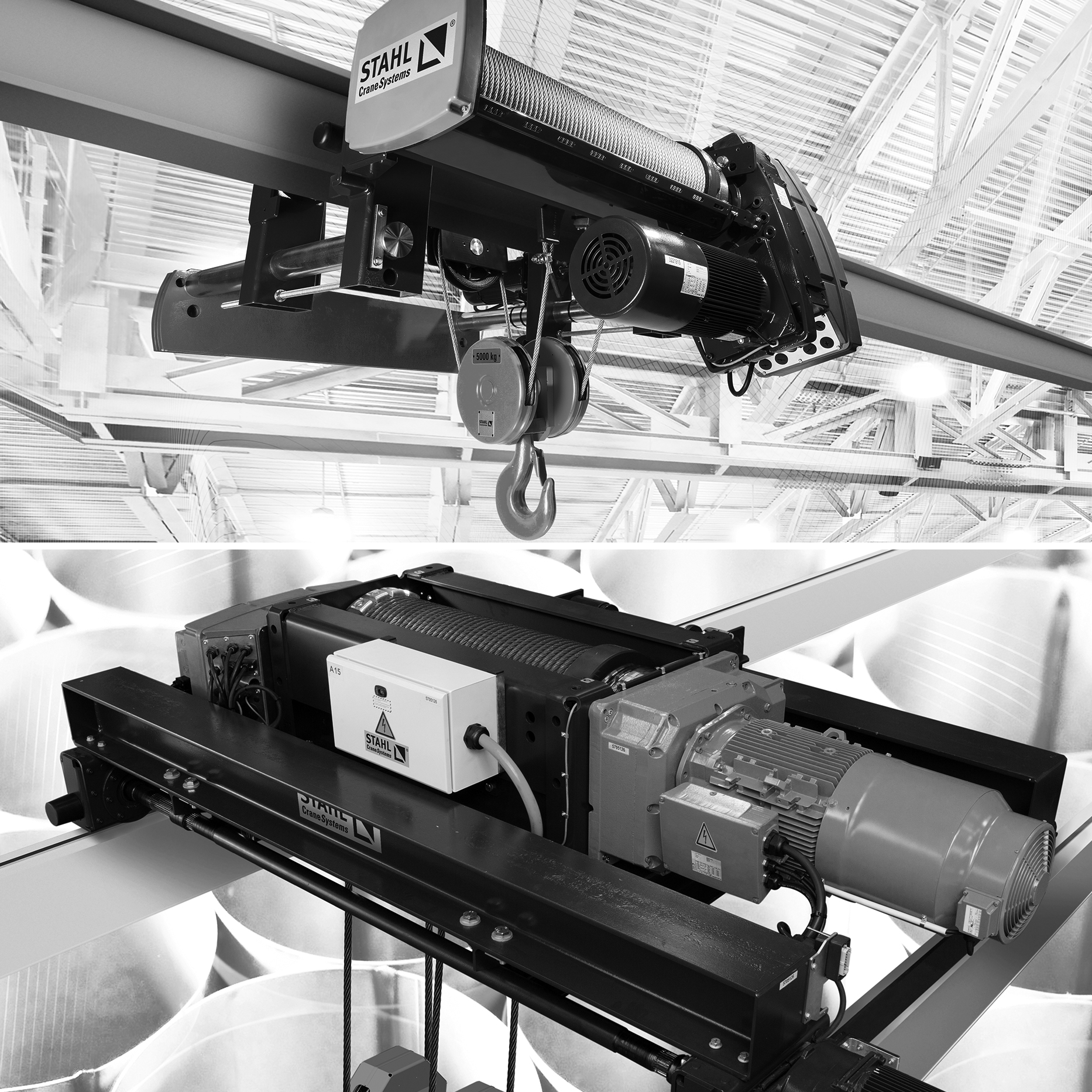

SH6050-16 8/2-1 L4

aux. SH5025-20 4/1 L3

For the maintenance of the sugar mills during the harvest season at a sugar mill, we needed to modernize old equipment. The SH60 with a 20-ton capacity turned out to be the ideal equipment for the maneuvers. Its compact design allowed for the inclusion of an auxiliary hoist, the SH50 with a 10-ton capacity.

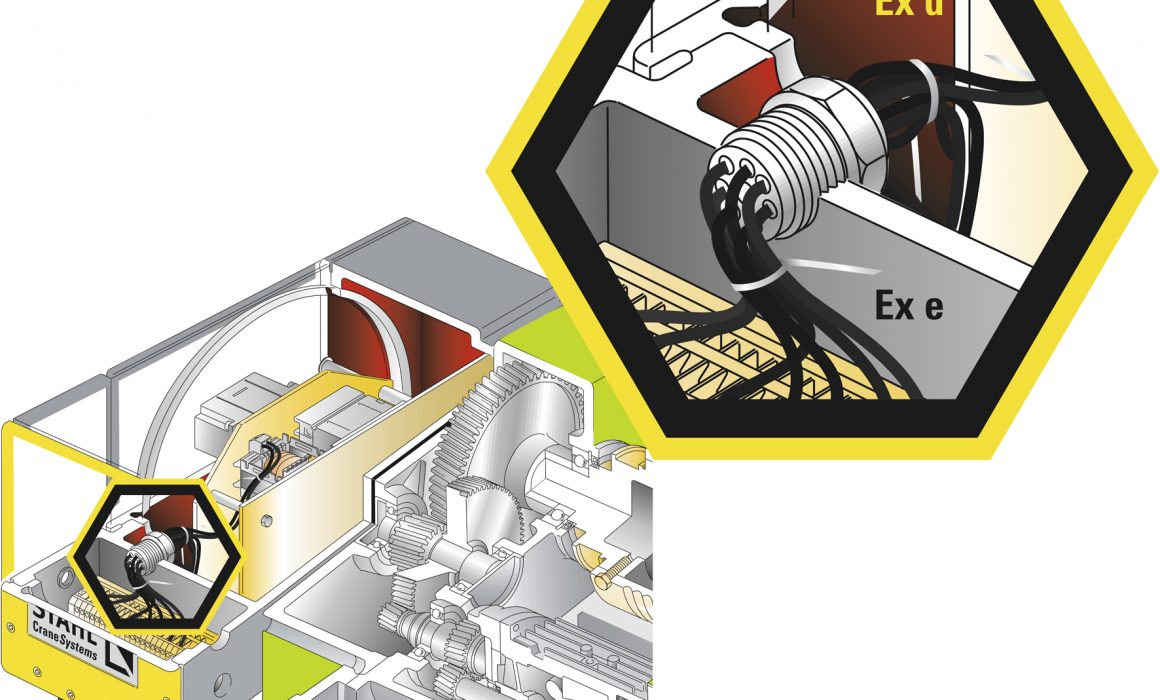

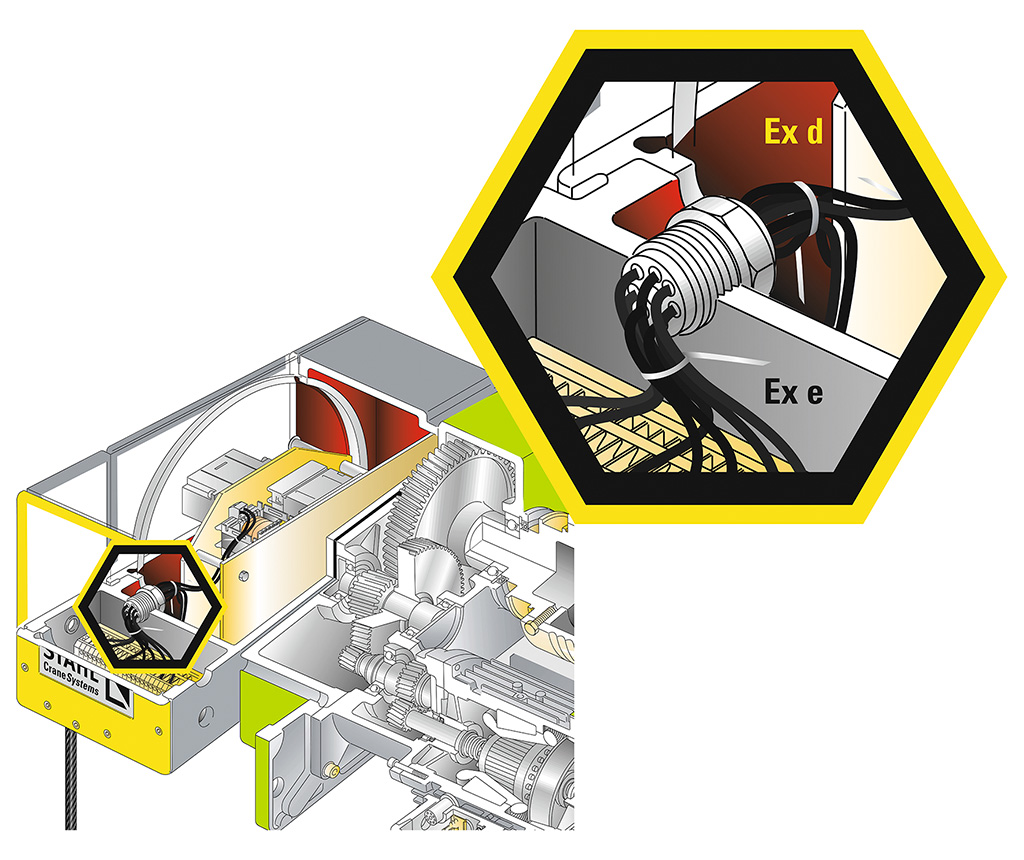

Design

• Two hoists, main SH60 and auxiliary SH50, mounted on a square profile frame assembled on a double-girder trolley.

• Special gauge

Hoists for individual use, namely "A or B"

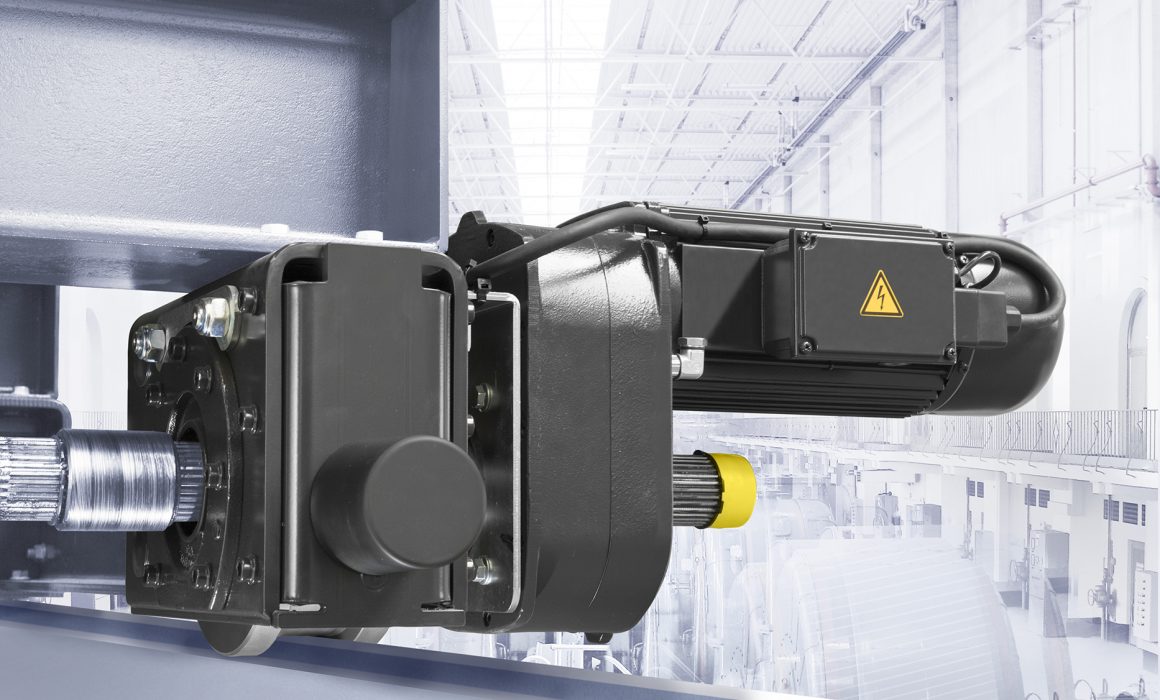

IP55 Protection

Electromechanical ratchet brake on the drum

Ratchet Brake

The project required a secondary brake to ensure that the rollers of the mills could be suspended indefinitely for access to the interior of the machinery. We included a ratchet brake mounted on the drum, which is ideal for the application.

The pawl mechanically engages, keeping the drum locked. It will only release the brake through an electromagnetic actuator.